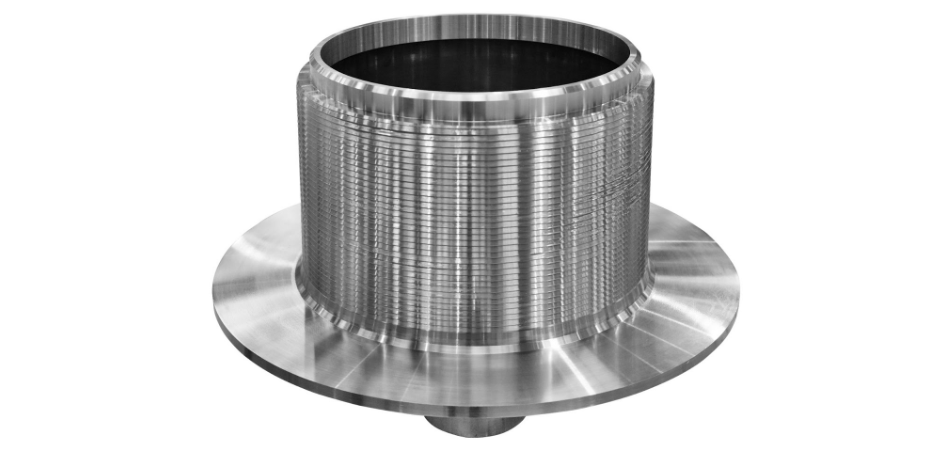

Certain complex specific industries require precision, resulting in higher demands for internally feature-specifically produced parts. Deep-hole drilling is an important process that allows the accurate production of parts.

With the latest technology and advanced deep-hole drilling techniques at Accurate Edge, parts can be manufactured to meet exact specifications. This ensures world-class quality, precision and reliability for even most demanding industries.

What is Deep-Hole Drilling?

According to VDI Standard 3210, deep hole drilling processes are manufacturing processes for machining of bore holes with diameters that’s between D = 0.2…2000 mm and whose drilling depth is typically greater than three times the diameter.

Deep hole drilling mostly differs from normal drilling in a way that depends on the drilling process and the drilling diameter, the cooling lubricant should be pumped to the cutting edges in large quantities and also under high pressure. This guarantees good cooling and also good lubrication of the contact areas between the workpiece as well as the cutting edge of the tool on the one hand as well as the workpiece and support pads of the tool on the other.

Moreover, the cooling lubricant continuously removes chips from the cutting zone, making surface-damaging and time-consuming chip removal strokes unnecessary and thus improves quality of the borehole and also the productivity of the processes.

Deep-hole drilling comes with significant advantages, including drilling in hard material, proximity tolerance, and maximization of manufacturing efficiency. Since industries have different demands, there is a need for more complicated parts with internal passages like lubrication or cooling channels. Deep-hole drilling performs these tasks accurately.

Applications of Deep-Hole Drilling

Deep-hole drilling is applied in most high-precision fields where some components have certain individual internal parameters. The most crucial applications are:

1. Oil & Gas Industry

- Drilling of long holes in drill collars, drill pipes, and subsea components.

- Manufacturing downhole tools and wellhead equipment.

2. Aerospace Industry

- Drilling landing gear components, hydraulic actuators, and engine parts.

- Precision bores for airframe structural elements.

3. Automotive Industry

- Machining crankshafts, camshafts, fuel injectors, and axle shafts.

- Production of shock absorber tubes and steering columns.

4. Medical Industry

- Producing orthopedic implants, such as bone screws, rods, and surgical instruments.

- High-precision drilling in stainless steel and titanium for medical devices.

Advantages of Deep-Hole Drilling

Deep-hole drilling is a process worth its weight in gold in so many ways that now, it is an indispensable high-precision production process. The foremost advantages are:

1. High Depth-to-Diameter Capability

- Allows drilling of holes much deeper than conventional methods.

- Ideal for applications requiring deep internal channels (e.g., oil & gas components, aerospace parts, molds, medical devices).

2. Excellent Straightness and Accuracy

- Specialized tooling and guidance (bushings or steady rests) maintain tight straightness tolerances.

- Capable of producing holes with minimal deviation over long depths.

3. Superior Surface Finish

- Produces smoother internal surfaces compared to standard drilling, reducing the need for further honing or finishing.

- Ideal for hydraulic and fuel systems that require smooth bore surfaces.

4. Efficient Chip Evacuation

- Tools are designed to evacuate chips continuously via internal coolant pressure or tooling geometry.

- Prevents chip buildup, which reduces risk of tool breakage and improves hole quality.

5. High Productivity

- Deep hole drilling machines are built for continuous and high-speed operations.

- Speeds up production of deep holes that would otherwise require multiple conventional passes.

6. Versatility

- Can drill a wide range of materials: from aluminum to hardened steel, superalloys, and titanium.

- Used in a variety of industries: oil & gas, aerospace, automotive, mold making, and medical.

7. Reduced Tool Deflection

- Specialized tooling and machine support minimize tool deflection even at long depths.

- Ensures concentric and true holes.

How Accurate Edge Can Help

We at Accurate Edge offer high-precision deep-hole drilling services. Our expert team takes pride in utilizing the latest technology and precision methods to deliver every project with maximum quality and precision.

Our drilling operations are complemented by experience spanning years; each part is produced to specific specifications. From design concept to final manufacturing, our main interest is low-cost, high-quality production that surpasses customer expectations.

Conclusion

Deep-hole drilling is an accurate procedure for high-precision use as it creates complicated internal feature pieces like cooling and lubrication passages. Its accuracy in creating increased precision, cooling, and capability to drill through hard materials contribute to its richness as a valuable technology in aerospace, automotive, and energy fields.

We utilize the most recent technology in deep-hole drilling at Accurate Edge to provide better-quality, affordable solutions that allow businesses to realize their manufacturing dreams.

Frequently Asked Questions

1. What is deep-hole drilling and how is it different from standard drilling?

Deep-hole drilling is a machining process used for holes with a depth greater than three times their diameter. Unlike standard drilling, it uses high-pressure coolant and specialized tools to ensure superior accuracy, lubrication, and chip removal during deep operations.

2. Which industries commonly use deep-hole drilling services?

Industries like oil & gas, aerospace, automotive, and medical rely on deep-hole drilling to create precise internal features in components such as crankshafts, hydraulic actuators, orthopedic implants, and subsea parts.

3. What are the main benefits of deep-hole drilling?

Deep-hole drilling offers high depth-to-diameter capabilities, excellent straightness and accuracy, improved surface finish, efficient chip evacuation, and higher productivity across materials like titanium, steel, and superalloys.

4. How does Accurate Edge ensure top-quality deep-hole drilling?

Accurate Edge uses advanced CNC machines, real-time monitoring, and expert operators to deliver custom, high-precision results. Our processes emphasize accuracy, speed, and cost-efficiency for demanding engineering applications.