Precision machining is crucial today in modern precision manufacturing as it provides complex parts with close tolerances. With industries needing more complex parts, advanced industrial machining technology is necessary to ensure accuracy and reliability during production.

In this blog, let us discover why precision machining is crucial and how services are necessary to ensure each part functions as intended.

Why Precision Machining Matters in Complex Manufacturing

Precision machine solutions allow parts to be manufactured in a manner that closely integrates into advanced assemblies with improved overall performance. They are needed for the following reasons:

- High Precision and Near Tolerances: Precision machine solutions allow parts to be manufactured in a manner that closely integrates into advanced assemblies with improved overall performance. These precision manufacturing techniques are essential in aerospace, automotive, energy, and defence industries.

- Facilitating the Machining of Complicated Structures: Techniques such as multi-axis CNC machining facilitate the manufacture of intricate parts with complex geometries. Facilitating compatibility with the growing demand for advanced, high-performance structures in all industries is essential.

- Less Waste and More Efficiency: Precision machining generates the best possible usage of material by reducing parts to accurate tolerances, which reduces waste. Precision machining maximizes material use and reduces scrap, which is critical in large-scale industrial machining operations where efficiency drives competitiveness.

- Enhancing Reliability and Durability: Components manufactured by precision machining are dependable and robust and resist harsh conditions such as high pressure and heat. They are required in the defence, medical devices, and petroleum and gas sectors, where there is no room for failure.

- Facilitation of Advanced Manufacturing Technology: Precision machining is facilitated through 3D printing and reverse engineering technologies that improve the capacity to design and manufacture. The components can be re-engineered and optimized using the application of the combination, and product innovation can be relentless.

Our Key Techniques in Precision Machining

Precision machining utilizes certain techniques that are applied to certain manufacturing challenges. Some of the most utilized methods are:

1. Multi-Axis CNC Machining

CNC machining is a basis for high-precision machining. Multi-axis CNC machines can mill complex shapes and provide accuracy never thought possible. These advancements have positioned CNC machining at the heart of industrial machining applications worldwide.

Multi-axis CNC machines can mill complex shapes and provide accuracy never thought possible.

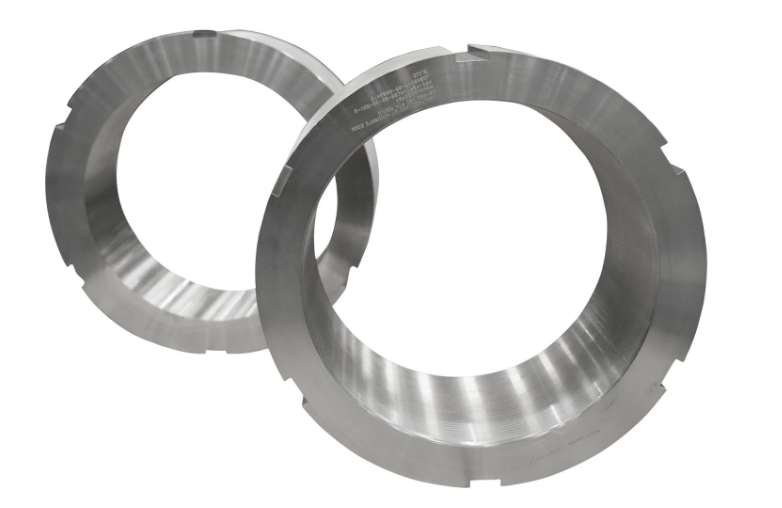

2. Precision Turning and Milling

Turning and milling are two of the most common operations in precision machining. Turning is achieved by rotating work material when the material is being machined using a cutting tool.

On the other hand, milling is achieved by a rotary cutting tool which removes material from fixed work material. The two processes can produce close tolerance and complex shapes, crucial in producing highly accurate components for precision manufacturing.

3. Precision Grinding and Finishing

Precision grinding is applied following initial shaping to position the part surface to precise measurements. Precision grinding is applied to fine-tune the dimensions of a component to close tolerances, with smooth finishes and close tolerances.

Finishing operations like polishing or coating are also applied to improve the functionality and cosmetic appearance of the part.

4. Complex Assembly and Integration

Accuracy machining isn’t merely manufacturing isolated components – it’s assembling and reassembling the stand-alone components into complex systems. A turbine, an engine, a sophisticated medical device – it doesn’t matter – all of the components are assembled in precisely the right place about each other. This is where industrial machining expertise plays a critical role, ensuring that every subcomponent aligns seamlessly within advanced systems.

Accuracy in precision machining is not so much technology as it is experience and attention skilled machinists have.

Conclusion

The importance of precision manufacturing in modern industries cannot be overstated, as demand for accurate, high-quality parts continues to rise. At Accurate Edge, we combine engineering excellence with advanced industrial machining capabilities to deliver results that exceed expectations.

Our commitment to excellence is aligned with global manufacturing standards such as those from the International Organization for Standardization (ISO) and the UAE’s Ministry of Industry & Advanced Technology

At Accurate Edge, we guarantee to provide cutting-edge machining services that exceed expectations. Our engineering capacity means that every job, whether complicated or simple, is carried out with unmatched precision, marking the highest quality and performance to your specifications.

Frequently Asked Questions

1. What is precision machining and why is it crucial for complex manufacturing?

Precision machining involves creating components with extremely tight tolerances, often down to thousandths of an inch. It’s a cornerstone of precision manufacturing, especially in aerospace, automotive, and medical devices.

2. How does precision machining help in producing complex designs?

With multi-axis CNC machining and advanced tools, precision machining enables manufacturers to create highly detailed parts with complex geometries that traditional methods cannot achieve.

3. How does precision machining improve efficiency and save costs in manufacturing?

By minimizing material waste, reducing rework, and ensuring accurate first-pass production, industrial machining solutions increase efficiency and lower costs for manufacturers.