If you’ve ever wondered why one shop recommends milling while another suggests turning or laser cutting, it usually comes down to matching your part with the right machine. Knowing the main cnc machine types helps you avoid guesswork and choose a path that’s faster, more accurate, and more cost-effective. And when you understand how different machining tools fit different jobs, it’s easier to talk the same language as your supplier and get the result you expect.

Why Knowing Different Types of CNC Machine Is Important

Not all machines do the same thing. Some excel at flat faces and pockets, some shine with round parts, and others are best for cutting sheet or hard-to-machine alloys. Choosing well saves time, reduces scrap, and improves quality. In short: match the machine to the job, and match the job to the machine. The more familiar you are with different types of cnc machines, the better you’ll choose for your CNC machine application, from quick prototypes to production runs.

What Are the Different Types of CNC Machines?

Before we get into the details, here’s a quick look at the basics. CNC machines come in different types—mills, lathes (for turning), routers, laser cutters, EDM, waterjet, grinders, and drills. Each one works best for certain materials, shapes, and tolerances. The right choice depends on your design, the material you’re using, the finish you want, and what the machine needs to do.

CNC Milling Machines

Definition:

A CNC milling machine is one of the most common type of CNC machines. It uses a rotating cutter to shape a fixed workpiece. It’s great for making flat surfaces, slots, pockets, and even detailed 3D shapes.

Applications:

- Aerospace: Brackets, housings, and structural parts needing precision faces and holes.

- Automotive: Engine blocks, transmission cases, and complex housings.

- Industrial Equipment: Gear housings and machine bases for alignment and stability.

Limitations:

- Not suitable for long cylindrical parts like shafts.

- Deep cavities or extreme angles may need multi-axis setups, increasing cost.

CNC Router Machines

Definition:

A CNC router is similar to a milling machine but designed for softer materials like wood, plastics, and composites. It’s fast and great for large sheets.

Applications:

- Furniture & Interiors: Cutting wood panels for cabinets and decorative elements.

- Signage & Displays: Quick profiles in plastics and composites for branding.

- Lightweight Components: Large sheets for architectural or transport use.

Limitations:

- Cannot handle hard metals or tight tolerances.

- Not ideal for heavy-duty industrial parts or precision engineering.

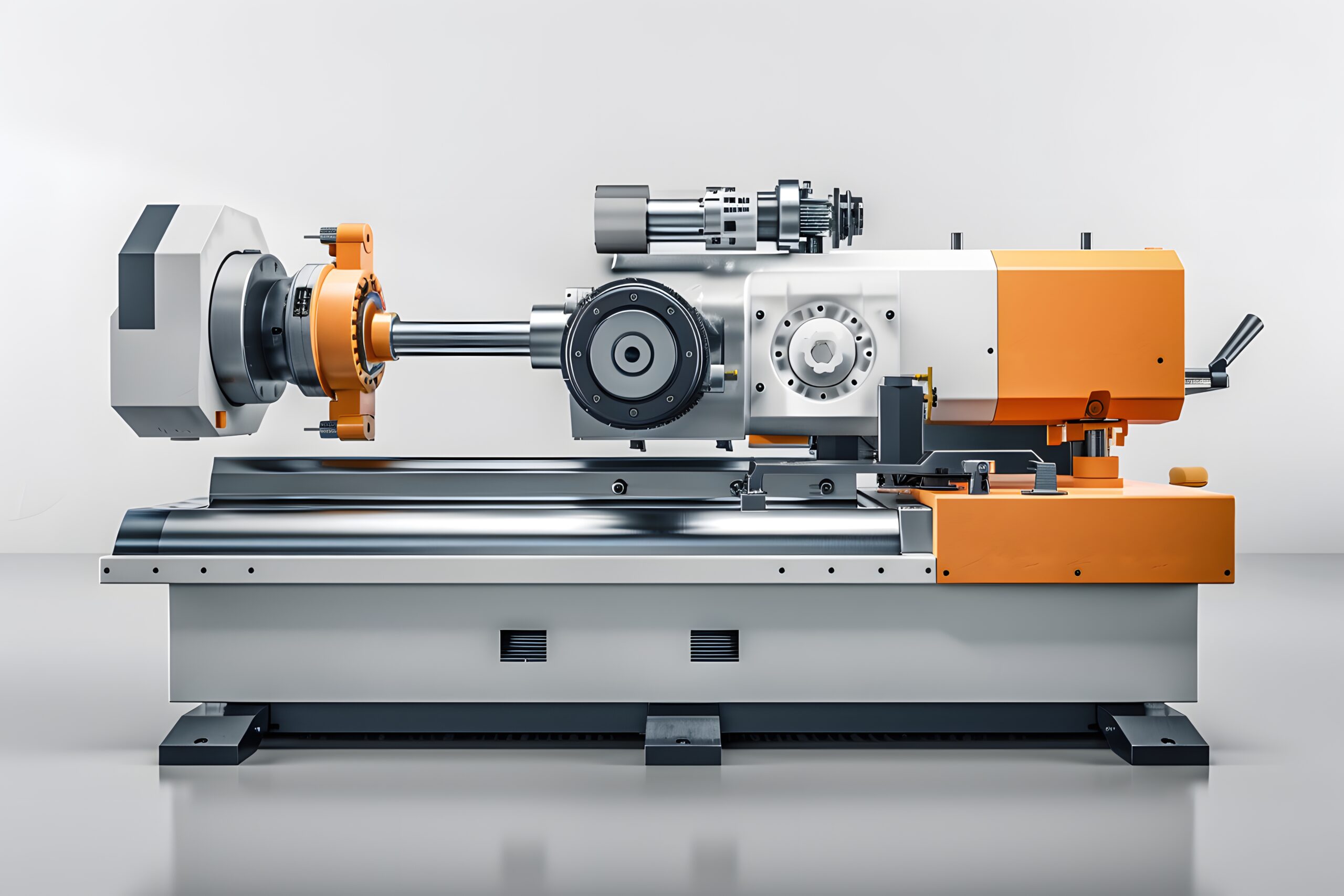

CNC Lathes and Turning Machine

Definition:

A CNC lathe rotates the workpiece while a cutting tool removes material, making it perfect for cylindrical parts.

Applications:

- Oil & Gas: Shafts, couplings, and valve components for drilling equipment.

- Automotive: Axles, bushings, and cylindrical engine parts.

- Industrial Machinery: Rollers and precision round components for smooth operation.

Limitations:

- Limited for parts with complex flat faces or pockets—milling does that better.

- Usually single-axis cutting, so intricate shapes need extra setups.

CNC Laser Cutting Machines

Definition:

Uses a focused laser beam to cut sheet metal with speed and precision, leaving clean edges.

Applications:

- Sheet Metal Fabrication: Cutting profiles for enclosures and brackets.

- Automotive & Aerospace: Lightweight panels and precision cutouts.

- Signage & Decorative Panels: Intricate designs with clean edges.

Limitations:

- Best for thin-to-medium sheet metal; struggles with very thick sections.

- Reflective materials like copper or aluminum can be challenging.

CNC Electrical Discharge Machines (EDM)

Definition:

Removes material using controlled electrical sparks. Wire EDM cuts profiles; die-sinking EDM creates cavities.

Applications:

- Tool & Die Making: Molds and dies with sharp internal corners.

- Aerospace & Automotive: Complex profiles in hardened steels.

- Medical Devices: Precision cavities and intricate shapes.

Limitations:

- Slower than milling or turning.

- Works only on electrically conductive materials.

CNC Waterjet Cutting Machine

Definition:

Uses a high-pressure jet of water (often with abrasive) to cut materials without heat.

Applications:

- Construction & Architecture: Cutting stone, glass, and composites.

- Industrial Fabrication: Metals without heat distortion.

- Marine & Oil & Gas: Components where heat-affected zones must be avoided.

Limitations:

- Kerf width and edge finish may need secondary finishing.

- Mostly limited to 2D profiles; not for complex 3D shapes.

CNC Grinding Machine

Definition:

Uses an abrasive wheel to achieve tight tolerances and smooth finishes, especially on hardened materials.

Applications:

- Automotive & Aerospace: Bearing surfaces and precision shafts.

- Tooling: Achieving tight tolerances and smooth finishes.

- Industrial Equipment: Hardened parts needing micron-level accuracy.

Limitations:

- Slow material removal—best as a finishing process.

- Requires precise setup and skilled handling.

CNC Drilling Machines

Definition:

Specialized for drilling clean, accurate holes. Can be standalone or integrated into milling centers.

Applications:

- Automotive & Aerospace: Hole patterns for fasteners and assemblies.

- Industrial Equipment: Repetitive drilling tasks in production runs.

- Fabrication: Countersinking and tapping operations.

Limitations:

- Limited to hole-making; cannot handle complex shapes alone.

- Often paired with milling for complete parts.

Automatic Tool Changer (ATC): Why It Matters

An ATC lets the machine swap machining tools automatically during a job—moving from a drill to a mill, to a tap, without manual intervention. That saves time, reduces human error, and keeps your cycle consistent. When you’re aiming for repeatable parts and shorter lead times, smart use of machining tools with an ATC is a simple win.

Things You Should Know Before Selecting a Type of CNC Machine

Picking the right types of CNC machning isn’t just about the machine—it’s about your part and process. Here are a few practical points to think through:

- Geometry: Is your part mostly flat surfaces and pockets, round features, or thin sheet profiles? Different machines handle these shapes better.

- Material: Steel, aluminum, plastics, composites, or hardened alloys—some machines work best with certain materials.

- Tolerance & Finish: Need tight fits or smooth surfaces? You might need milling plus grinding, or turning followed by honing.

- Volume & Lead Time: Are you making one prototype or planning regular production? Your choice will affect speed and cost. CNC machining helps in improving productivity

- Post-Processing: Coatings, plating, honing, or heat treatment can influence which machine you start with.

- Application: Are these parts for assembly, maintenance spares, or custom fixtures? Each use case leans toward a different CNC setup.

Why Choose Accurate Edge

You need CNC machining services in uae that looks over your drawing, asks the right questions, and recommends the best course of action—using waterjet or laser for profiles, turning when it’s better, milling when it fits, and finishing steps that make your part last. You can move from design to delivery without changing vendors thanks to integrated services like honing and plating, local support, and dependable scheduling. Accurateedge is a good place to start if you’re looking for something online.

Conclusion

Knowing the different types of CNC machines makes planning much easier. You’ll know what to expect, how to schedule work, and how to compare quotes. There’s a setup for every need—whether it’s durability, speed, or accuracy. Use milling for prismatic parts, turning for round components, laser or waterjet for sheet profiles, and grinding or EDM for complex shapes and fine finishes. Pick the right machine for the job, and you’ll spend more time shipping parts and less time fixing problems.

Frequently Asked Questions

Q1: How many different CNC machines are there?

There isn’t one official number, but most shops use a core set of CNC machine types: milling, turning (lathes), routers, laser cutters, EDM, waterjet, grinding, and drilling. Some shops also use hybrid or multi-tasking machines that combine different operations.

Q2 What are the most popular types?

For general manufacturing, mills and lathes are the most common. A CNC milling machine handles faces, pockets, and threads, while turning is used for shafts and round features. Routers are popular for plastics and wood. Laser and waterjet machines are used for sheet profiles, and grinding, or EDM is chosen for fine finishes or complex shapes.

Q3 How do you operate a CNC machine safely and efficiently?

Keep it simple: start with a clean setup, load the right tools, verify the program, and do a controlled first run. Measure the first part, make small adjustments, and only then scale up. If you’re unsure which path to take, discuss your CNC machine application with the shop—they’ll help guide the workflow.