Enhanced Strength Through Long Jobs Machining and Honing

Enhanced Strength Through Long Jobs Machining and Honing

Why Strength is Important in Heavy Engineering

Heavy engineering parts need to absorb impact, fatigue, and high stress. Their strength to do so depends on tensile strength, yield strength, impact resistance, and fatigue life—all critical in preserving operating integrity in states of high-stress conditions.

How Long Machining Jobs Provide Strength

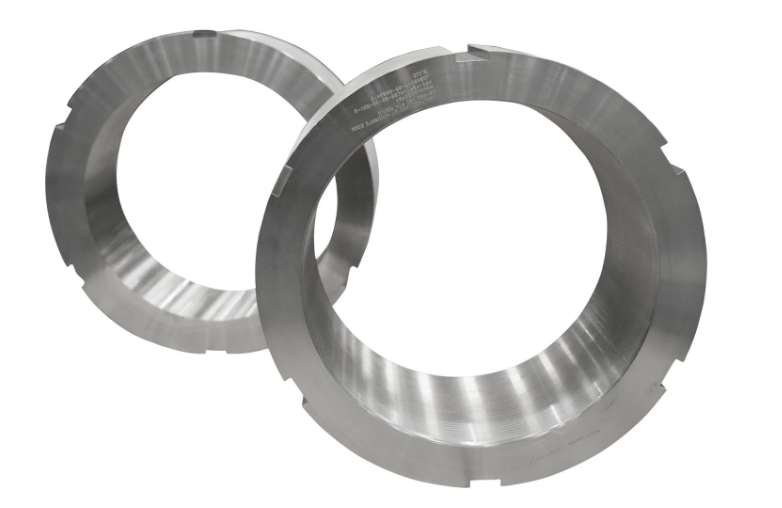

- Eliminating Internal Defects: The machining accuracy eliminates voids, segregations, and inclusions that lead to stress concentrations, greatly enhancing fracture resistance.

- Optimized Grain Flow: Long machining operations orient the grain structure in loading directions, increasing material toughness and minimizing weak spots.

- Stress-Relief Machining: Controlled-depth machining and heat treatments such as annealing minimize internal stresses generated during forging or

- Surface Hardening: Burnishing and roller hardening create compressive residual stresses, enhancing fatigue strength and surface wear

Example: Forged steel components precision machined possess 26% yield strength over cast components, leading to extended lifespan and dependability.

2. Precision Enhancement Through Honing

While strength is a factor in durability, long jobs machining and honing cannot be eliminated so that measurements remain accurate, thus enabling components to fit tightly in intricate industrial systems

How Honing Achieves High Precision

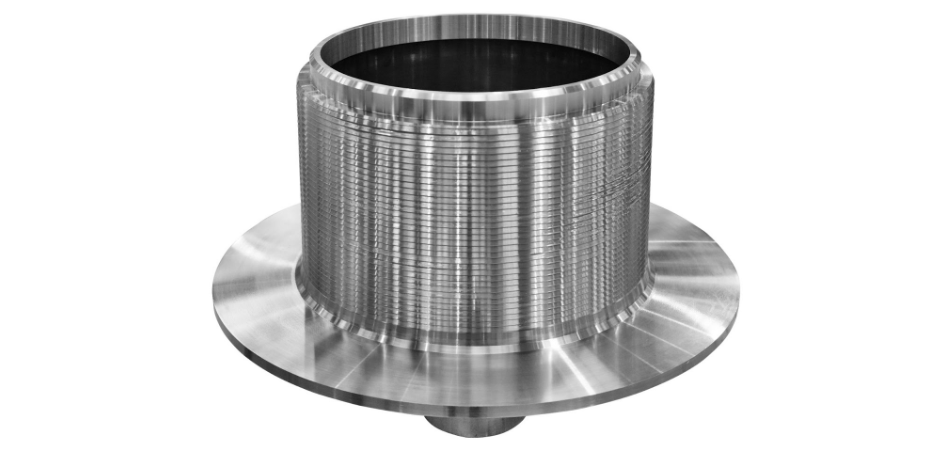

- Achieving Near Tolerances: Honing achieves tolerances of as close as 0001 inches (2.5 microns), necessary in hydraulic cylinders, power transmitting shafts, and landing gears in the aircraft industry.

- Geometric Error Correction: It corrects for taper, waviness, and out-of-round conditions, improving circularity and straightness for better

- Improved Surface Finishing: Honed surfaces enhance lubrication retention, reducing friction and improving wear

Example: For hydraulic cylinders, honing to tolerance guarantees smooth piston travel, leak-free, and highest-pressure efficiency, an essential industrial hydraulic application requirement.

3. Optimization of Performance through Machining and Honing

Long-term component performance relies on wear resistance, vibration damping, and high-speed operating efficiency—all areas where long jobs machining and honing play a critical role.

How Machining and Honing Enhance Performance

- Longer Lifespan with Reduced Friction: Finishing with extended surfaces maintains lubricity for longer periods, avoids heat buildup, and limits

- Less Noise and Vibration: Effective mass balance through machining eliminates unwanted rotational

- Higher Operating Speeds with Virtually No Vibration: Long honing-induced near-perfect roundness enables shafts to run at high speeds without vibration failure.

Example: High-precision power transmission shafts honed in windmills greatly enhance rotational efficiency and life, providing smooth power generation in renewable power systems.

4. Integration of Machining and Honing in Heavy Engineering

How Machining and Honing Integrate for Maximum Efficiency

- Although machining provides structural integrity, precision tuning of dimensional tolerance and surface finish is performed by honing. They yield high-performance parts that are of high industry standards when integrated.

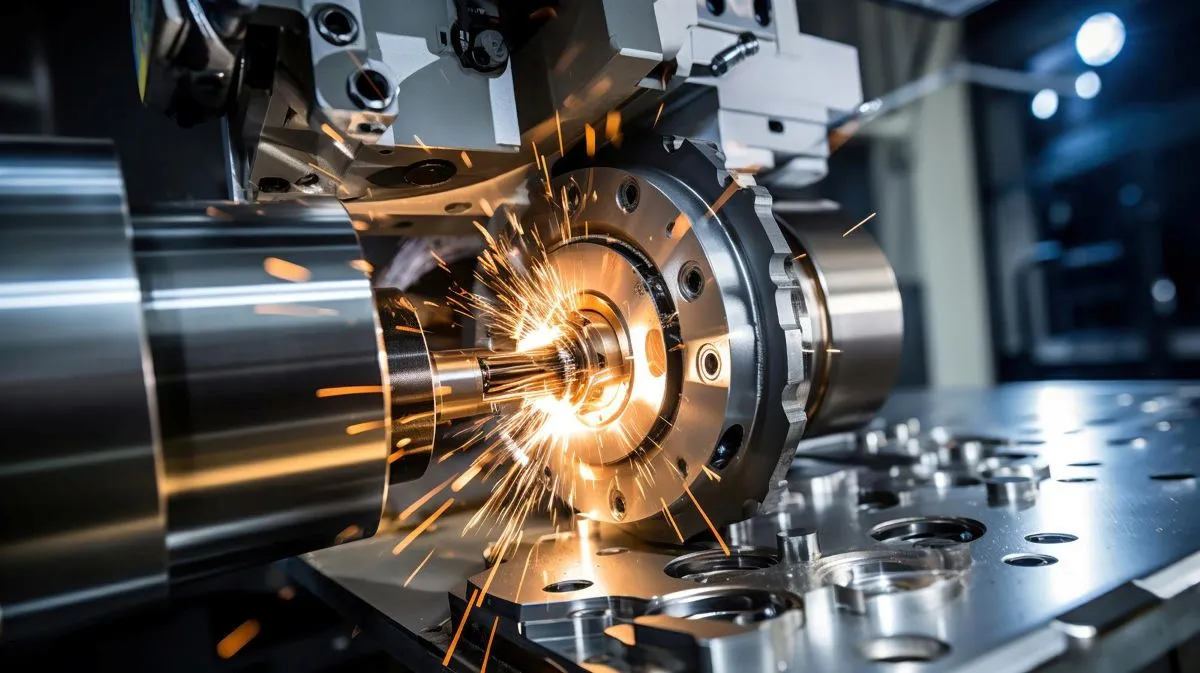

- Automation and Robotics: Sophisticated robotic units are precision honing techniques for large-scale machining, minimizing inaccuracies and maximizing production

Example: Shipbuilding shafts are CNC machined for initial material removal, then honed to improve suiface texture for maximum hydrodynamic efficiency and prolonged operating reliability.

Adaptive Machining of Extended Parts: CNC-operated processes adjust dynamically to ensure continuous accuracy on extendedReal-Time Monitoring and Compensation: In-process sensors monitor machining deviations and provide real-time compensation to preserve tolerance at

5. Cost Efficiency and Sustainability Gains

Deep hole drilling in heavy engineering processes are often cash-strapped due to material expenses, production inefficiencies, and environmental constraints. Machining and honing neutralize these issues through augmented efficiency and minimized waste.

How Machining and Honing Boost Cost Efficiency

- Near-Net Shape Machining: Reduces material removal, decreasing scrap rates and raw material

- Optimized Toolpath Planning: Increases cutting efficiency, resulting in longer tool life and shorter machining time.

- Coolant Recycling Systems: Decreases waste disposal cost and enhances overall machining efficiency, making the process cleaner.

Environmental and Sustainability Benefits

- Energy-Efficient CNC Machines: Reduced power consumption and operating

- Eco-Friendly Honing Abrasives: Encourage sustainability without compromising precision or performance.

Example: Aerospace companies save millions of dollars every year by applying high-precision honing, minimizing material loss, and increasing sustainability without compromising the best performance standards.

Conclusion

Long jobs machining and precision honing jobs cannot be substituted in heavy engineering, which enhances strength, accuracy, and long-term performance. The advanced processes provide ultimate durability, minimize wear, and increase operating efficiency.

By adopting automated machining, adaptive honing, and in-process monitoring in real-time, industries attain more productivity, fewer failure modes, and enhanced service lifetimes.

Accurate Edge is at the forefront of this, with high-end machining solutions for high-end deep hole drilling in heavy engineering requirements that evolve constantly. Businesses that partner with Accurate Edge gain access to new machining technologies that enhance toughness, reduce operation costs, and set the pace in the modern manufacturing environment.

Frequently Asked Questions

1. How does long jobs machining enhance strength in heavy engineering parts?

Long jobs machining eliminates internal defects, optimizes grain flow, and induces surface hardening—enhancing toughness, fatigue resistance, and overall structural integrity.

2. What is the role of honing in achieving precision?

Honing improves dimensional accuracy, corrects geometric errors like taper and waviness, and enhances surface finish, making it ideal for hydraulic cylinders and rotating shafts.

3. How do machining and honing improve equipment performance?

They reduce friction, noise, and vibration while increasing operating speeds and lifespan. These benefits result from optimized surface finishes and mass balancing.

4. Are machining and honing processes sustainable and cost-effective?

Yes. Near-net shape machining, toolpath optimization, and coolant recycling reduce waste and energy use, making the processes environmentally friendly and cost-efficient.

Recent Post

20 May 2025

Build a Culture of Safety in Our Organization

20 May 2025

The Critical Role of Precision Machining in Modern Manufacturing

20 May 2025

How CMM Inspection and Reverse Engineering Drive Manufacturing Excellence

20 May 2025

Delivering Depth and Precision—Your Partner in Deep Hole Drilling Excellence

26 Mar 2025

How CNC Machining Services Improves Productivity?

Related Post

Build a Culture of Safety in Our Organization

A strong safety culture is the backbone of any successful

The Critical Role of Precision Machining in Modern Manufacturing

Precision machining is crucial today in manufacturing as it provides

How CMM Inspection and Reverse Engineering Drive Manufacturing Excellence

Reliability and accuracy in each component are necessary in the

Delivering Depth and Precision—Your Partner in Deep Hole Drilling Excellence

Certain complex specific industries require precision, resulting in higher demands

How CNC Machining Services Improves Productivity?

How CNC Machining Services Improves Productivity? CNC machining services are

Enhanced Strength Through Long Jobs Machining and Honing

Enhanced Strength Through Long Jobs Machining and Honing Enhanced Strength