Understanding CNC Machining in Modern Manufacturing

Today, the industrial landscape is advancing and is also very competitive in terms of time. Therefore, it causes constant pressure to deliver components that are complex, accurate, and faster. In standard manufacturing, there is often a need for short runs within tight tolerances, with designs and the right materials. This is where custom CNC Machining […]

The Importance of Quality Control in Precision Machining: Ensuring Safety and Reliability in Precision Part Manufacturing

In high-end, regulated manufacturing environments, quality cannot be compromised. For industries that rely on high-accuracy components, maintaining consistency, traceability, and compliance at peak levels throughout every stage of production is an absolute requirement. That’s why quality control matters in the precision part manufacturing for components used in safety-critical applications. Whether it’s an aerospace system or […]

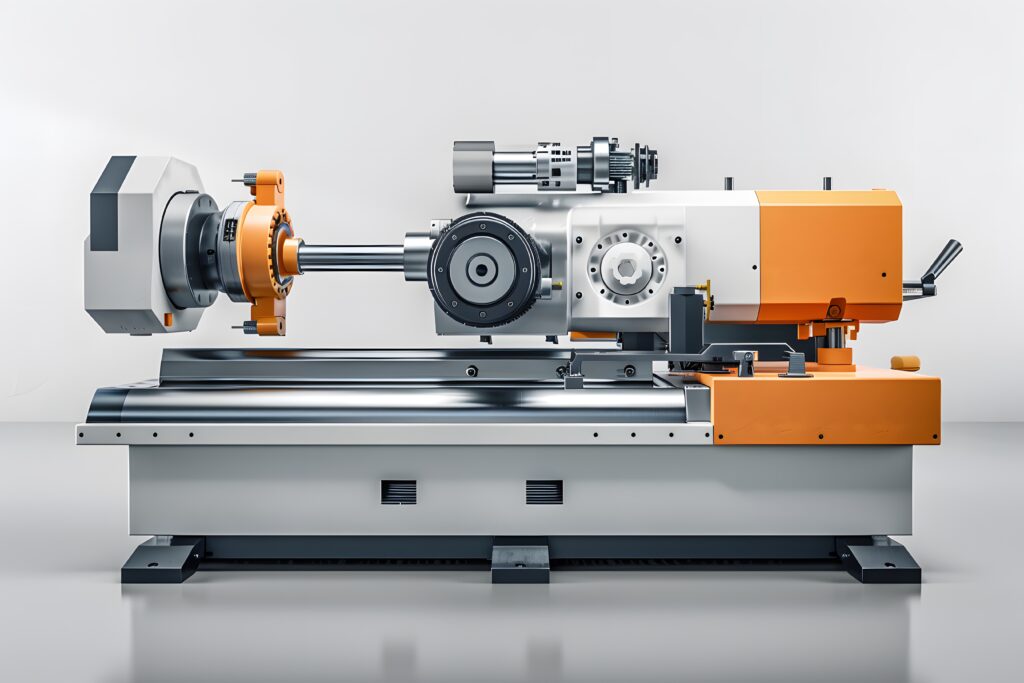

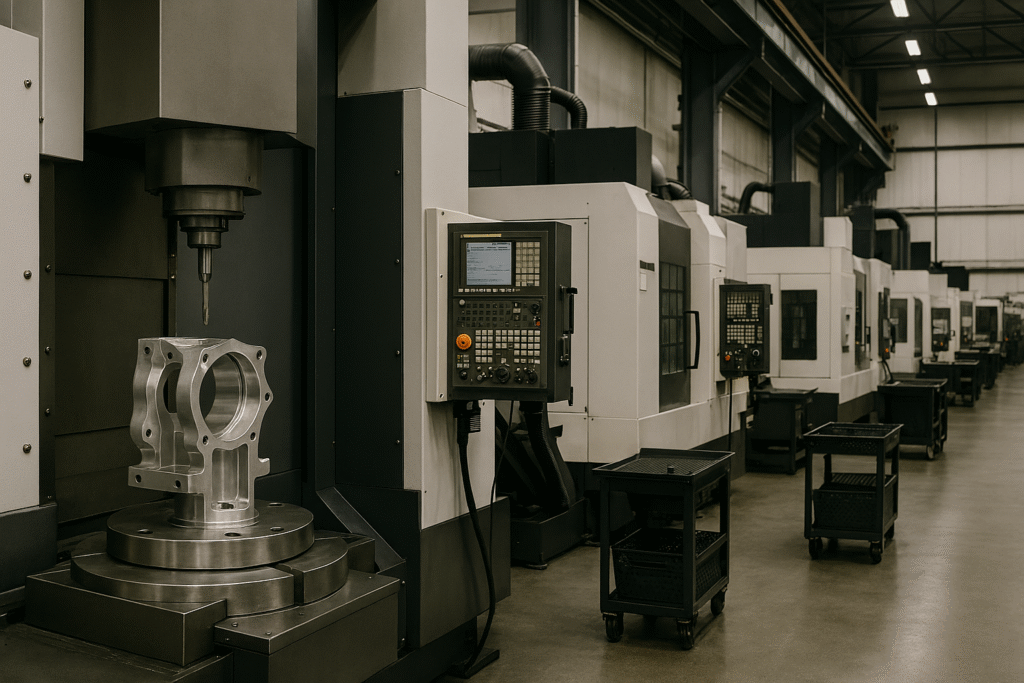

Types of CNC Machines and Their Applications

If you’ve ever wondered why one shop recommends milling while another suggests turning or laser cutting, it usually comes down to matching your part with the right machine. Knowing the main cnc machine types helps you avoid guesswork and choose a path that’s faster, more accurate, and more cost-effective. And when you understand how different […]

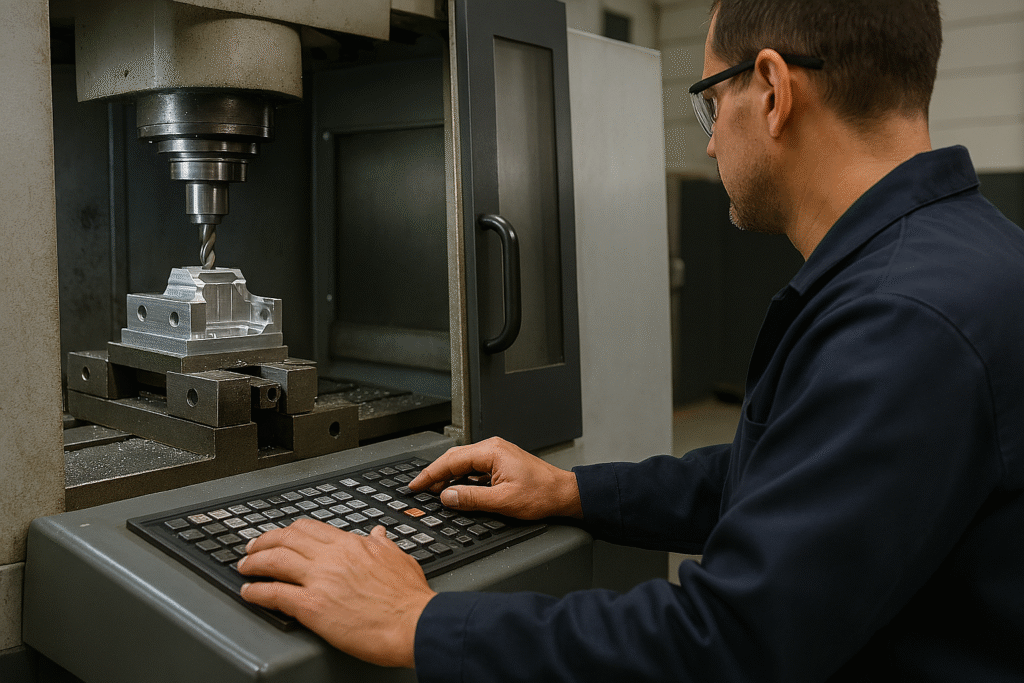

What Is CNC Machining? How It Works, Benefits & Applications

Precision parts are the result of careful planning, reliable setups, and effective technology. If you are considering machining for production, maintenance, or prototyping, learning about CNC is a good place to start. Accurate Edge provides CNC machining, Industrial Coating , Welding and Repair in the UAE—so you can go from idea to finished component with […]

The Future of High-Integrity Components: The Role of Precision Machining in Innovation

As industries push the boundaries of performance, safety, and reliability, the demand for high-integrity components is skyrocketing. These components are essential in sectors where failure is not an option—such as aerospace, medical devices, energy, and defence. To meet these demands, manufacturers are turning to precision machining, a process that enables the production of complex parts […]

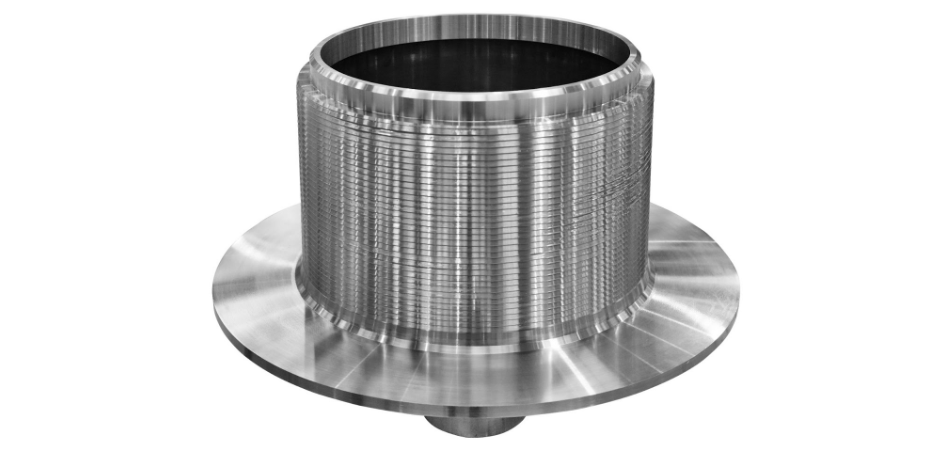

Precision Machining for Oil & Gas Components in the UAE

The oil and gas industry works in some of the toughest conditions on earth. From offshore rigs to desert pipelines, equipment has to keep performing under extreme pressure, heat, and exposure to corrosive elements. Precision machining plays a vital role in ensuring that critical components meet these challenges with accuracy, durability, and consistency. In the […]

Solving Complex Manufacturing Challenges with Custom CNC Machining

In today’s fast-evolving industrial manufacturing landscape, businesses face increasingly complex production challenges—from intricate part geometries and tight tolerances to material compatibility and cost-efficiency. Navigating today’s manufacturing challenges isn’t just about sticking to old playbooks, it demands precision and adaptability at every step. That’s where Accurate Edge comes in. We know CNC machining isn’t just a […]

Improving Corrosion Resistance in Solar Infrastructure with Advanced Plating

As solar energy plays an important role in sustainable development, especially in areas like the UAE, the durability of solar infrastructure is receiving more attention. Solar panels, mounts, and connectors face harsh conditions. Extreme heat, humidity, and salinity can increase the rate of corrosion. improved plating technologies helps tackle these issues by improving surface protection […]

10 Key Manufacturing Processes Explained (And Where CNC Machining Fits In)

Manufacturing is the keystone of contemporary industry, transforming raw materials into an apparently endless number of finished goods. To appreciate the sophistication and accuracy of the things we consume every day, knowledge of the primary manufacturing processes is important. In this blog, we discuss the 10 important manufacturing processes, how they operate and where the […]

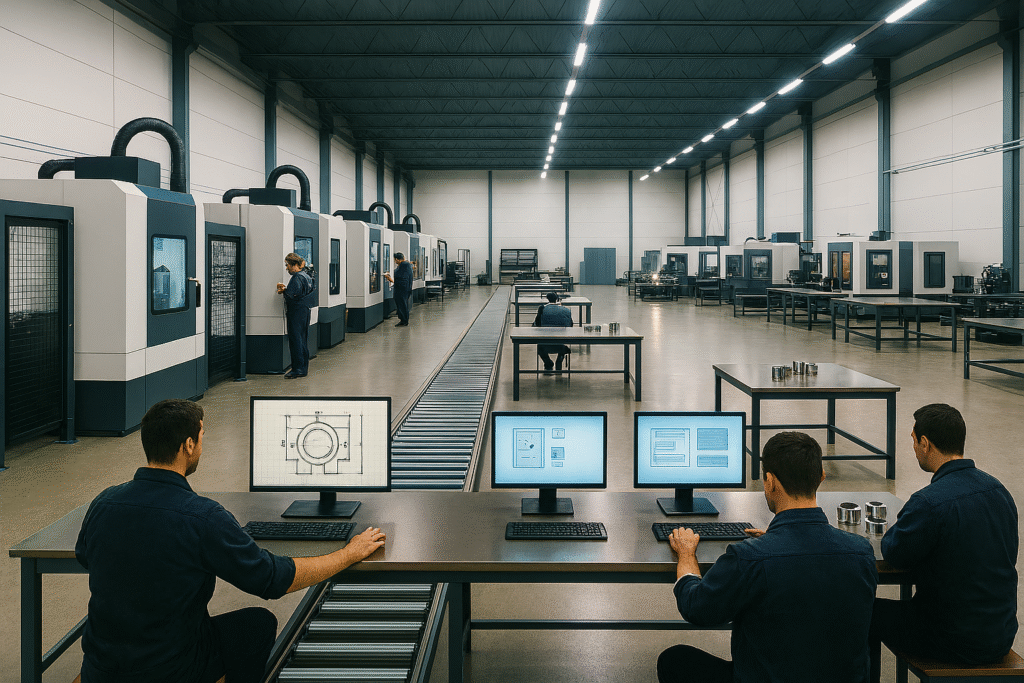

CNC Machining Capabilities Explained: From Design to Final Product

Accuracy, intricacy and productivity characterize contemporary manufacturing and CNC machining is at the heart. Employed in Aerospace, Oil and Gas , Medical and Automotive manufacturing sectors, CNC machining delivers parts with tolerances as close as ±0.001 inches and represents more than 75% of precision component production. Highly mechanized subtractive manufacturing, this process demonstrates the immense […]

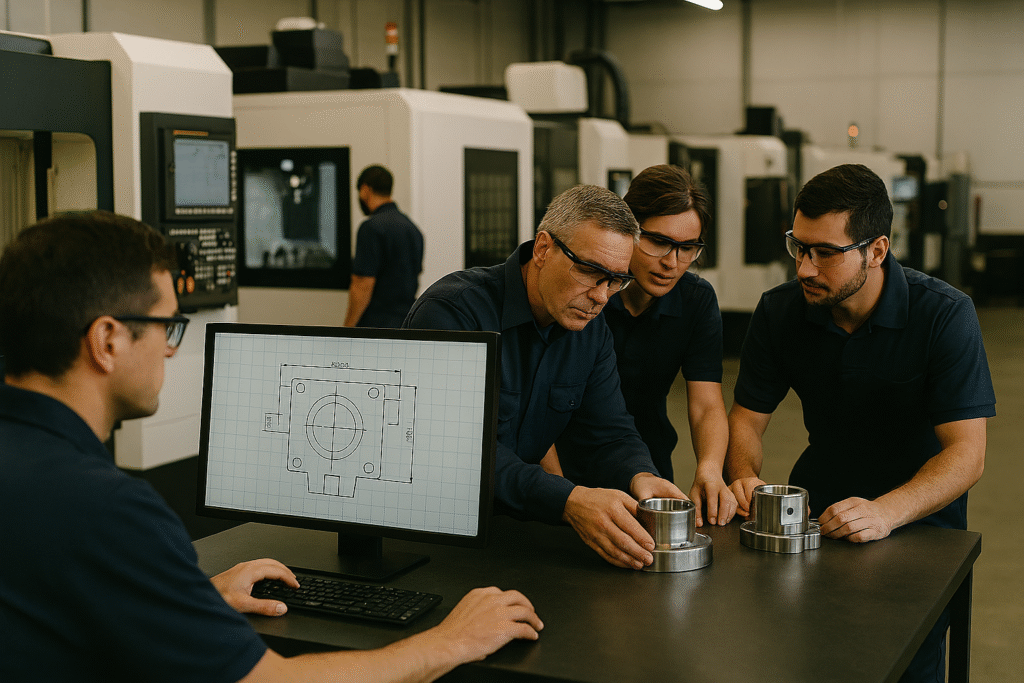

Custom Machining Solutions: Delivering Precision Parts for Critical Industries

In aerospace, medical, defense, automotive and oil and gas applications, accuracy is not only necessary but downright vital. These sectors require machined components that are ultra-precise and totally reliable. Routine manufacturing techniques simply aren’t up to the task when you require complex geometry and super-close tolerances. This blog explains how custom machining solutions, skilled capabilities, […]

Mastering the Complexities of CNC Machining for High-Integrity Components

In precision manufacturing CNC machining is a cornerstone technology particularly for high-integrity parts essential to aerospace, medical, automotive, Oil and Gas and power generation markets. Such parts require superior accuracy, high-surface quality and uncompromising material integrity to guarantee safety, performance and durability. Meeting these demands involves overcoming several intricate challenges across design, process control, tooling […]

High-Performance Manufacturing: Why Precision Matters for Safety-Critical Industries

In sectors where reliability and safety are not a negotiable aspect, accuracy isn’t merely a technical necessity but the basis of everything. Medical devices, aerospace, defense, automotive and nuclear industries function under harsh conditions where any minor deviation may result in catastrophic effects. Precision machining guarantees each component, each part and each process is constructed […]

Leading the Way in Advanced Precision Machining for High-Integrity Parts

In sectors where failure isn’t an option like aerospace, medical, defense and high-performance automotive there advanced precision machining is the cornerstone of quality, safety and performance. These industries depend on high-precision machining solutions to produce complex parts with ultra-tight tolerances and superior surface integrity. It’s not simply a matter of producing parts but producing them […]

The Power of Coatings: How Surface Treatments Improve Component Performance

Surface treatments and coatings are advanced engineering technologies that greatly extend component performance in harsh environments. By modifying surface properties without altering underlying material coatings provide a highly effective, cost-efficient means of increasing wear resistance, corrosion protection, thermal stability and functionality. Aerospace, automotive, heavy machinery, electronics and medical devices industries rely a lot on coatings […]

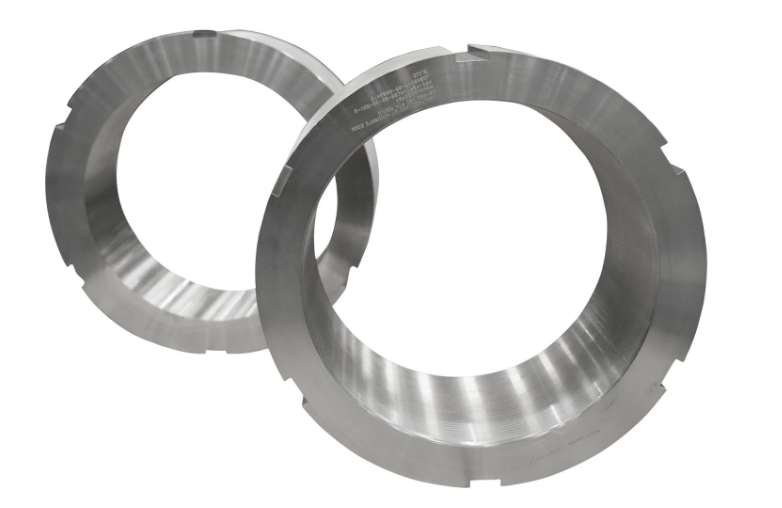

How Precision Machining Sets the Standard for Quality in the Oil & Gas Industry

The oil and gas sector works under some of the toughest conditions on Earth. High pressure, unstable temperature, corrosive liquids and also continuous mechanical load render reliability an irrevocable requirement. The global downhole component machining market is projected to grow from USD 8.3 billion in 2024 to USD 13.7 billion by 2034, highlighting the rising […]

Unlocking the Potential of Hard Gold Plating and Its Industrial Applications

In some industries, such as aerospace, electronics, defence and medical devices, everything has to work flawlessly each time. Parts for these industries have to be strong, dependable and well-developed. That is why many companies employ CNC machining to make parts with extremely precise measurements. Shaping the parts is not enough, however, how the surface resists […]

The Evolution of Precision Machining: From Manual to CNC Excellence

Precision machining has come a long way since it began, progressing from manual processes to advanced Computer Numerical Control (CNC) technology. Throughout this evolution, the precision, efficiency and flexibility of manufacturing processes have improved remarkably. In this blog, let’s understand the transition from manual machining to CNC precision Machining and embrace the technological strides that […]

Innovations in Coating Technologies: Enhancing Durability and Performance

In industries where performance and safety are very important like oil and gas, aerospace, petrochemical and industrial manufacturing, component reliability is essential. At present the demand for next-generation coating solutions that ensure exceptional durability and performance has never been greater. Metal protective coatings play an important role in preserving the integrity of components improving their […]

The Role of Deep Hole Drilling in Precision Manufacturing

In precision manufacturing, producing perfect, high-tolerance parts is a must. Deep hole drilling (DHD) is a key process, providing ultra-deep, straight and accurate holes in a range of materials. Coupling with Industry 4.0 systems provides real-time data collection, machine learning and predictive maintenance, setting DHD machines apart as not merely high-precision equipment but as intelligent […]

How CMM Inspection and Reverse Engineering Drive Manufacturing Excellence

Reliability and accuracy in each component are necessary in the contemporary manufacturing era. Two technologies, industrial inspection CMM and CMM reverse engineering, are forces that transform these priorities into reality. Precision and accuracy are the utmost priorities at Accurate Edge. This blog explains why these technologies are necessary and how they enhance manufacturing processes. What […]

What is Electroless Nickel Plating (ENP), and how does it benefit

When it is necessary to lengthen life and guarantee the reliability of your components in harsh conditions, electroless nickel plating (ENP) is among the most effective and dependable alternatives. This sophisticated coating technology provides substantial gains in durability and resistance to corrosion. Indeed, substrate hardness can be raised as much as 53% following ENP coating […]

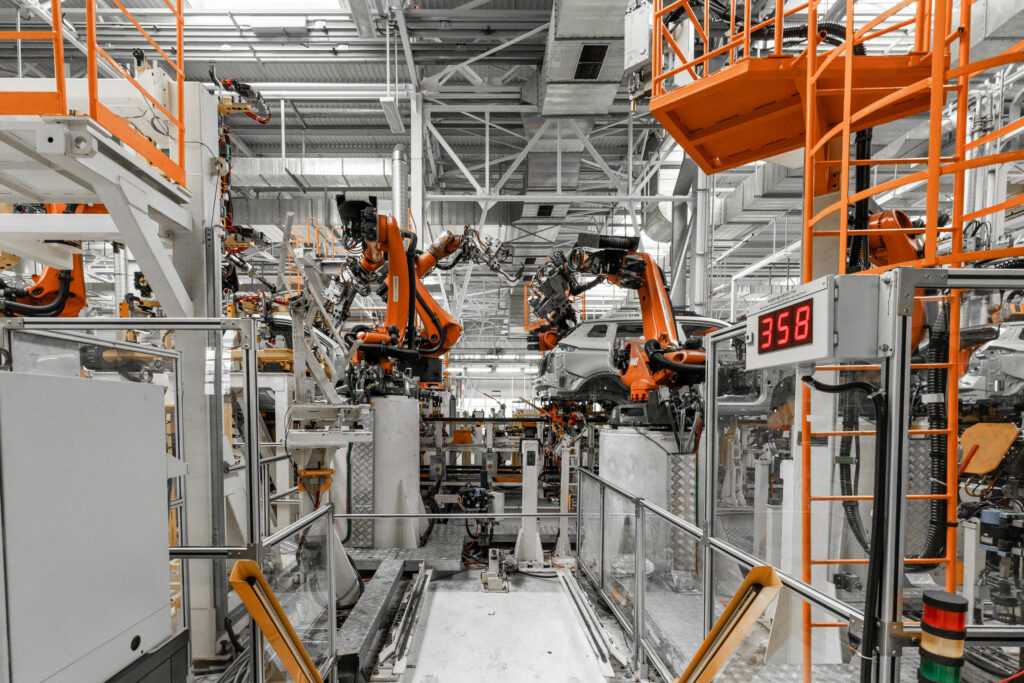

How Our Precision Machining Services Can Transform Your Business

Accuracy machining is important in order to satisfy the increasing need for high-performance, high-quality components. The worldwide precision engineering machines market will expand from $20.09 billion in 2025 to $29.16 billion in 2034 at a CAGR of 4.23%. It is stimulated by the use of CNC machines and robotic systems that allow manufacturers to handle […]

The Power of Coatings: How Surface Treatments Improve Component Performance

Surface coatings are important for optimizing performance of components in industries, improving wear resistance, corrosion protection, friction reduction and thermal stability. The industrial coatings market globally is expected to touch USD 116.68 billion in 2030 at a CAGR of 3.8%. The rise is facilitated by accelerated use of coatings for Oil and Gas, Automotive Maintenance, […]

What is Precision Machining? Benefits, Types, and How It Compares to Traditional Manufacturing

If you’ve ever wondered how airplanes stay safe at 35,000 feet or how medical implants fit perfectly inside the human body, the answer often comes down to one thing: precision machining. It’s not just a buzzword—it’s the backbone of modern manufacturing. Whether you’re in the industry or just curious, this guide will walk you through […]

Advanced Welding and Repair Solutions with Accurate Edge Technology

Our Welding Division at Accurate Edge is a legend for technology and precision metal fabrication. We provide a variety of high-precision machining and welding operations. Our repair and welding is based on leading technology, skilled craftsmanship and uncompromised quality. Whether a vital aerospace repair or a routine industrial maintenance procedure, we assure each weld that […]

Why Induction Hardening is a Budget-Friendly Replacement for Carburizing

Induction hardening is becoming an affordable and cost-effective substitute for carburizing heat treatment. Research indicates an 85% decrease in heat treatment process steps when migrating from traditional gas carburization to DPIH. This blog discusses how induction hardening cuts costs, processing times and environmental footprint without sacrificing high-quality hardening outcomes. What is Carburizing? Carburizing is a […]

Top Benefits of Using PTFE Coating in Industrial Applications

Polytetrafluoroethylene (PTFE) is one of the most versatile polymers with outstanding advantages employed in a number of industrial procedures. Industrial PTFE coating is widely used across industries from precision machining to oil and gas owing to its excellent PTFE coating advantages, such as durability, chemical resistance, and thermal stability.. The blog educates us about the […]

Accurate Edge QHSE – Driving Quality, Health, Safety, and Environmental Excellence

Accurate Edge sets a benchmark in Quality, Health, Safety and Environmental (QHSE) excellence. By integrating advanced systems, technology and culture for continuous improvement, our organisation surpasses international standards for the well-being of its people, stakeholders and the environment. The QHSE framework of Accurate Edge is discussed in this blog, and our company’s business strategy is […]

The Critical Role of Precision Machining in Modern Precision Manufacturing

Precision machining is crucial today in modern precision manufacturing as it provides complex parts with close tolerances. With industries needing more complex parts, advanced industrial machining technology is necessary to ensure accuracy and reliability during production. In this blog, let us discover why precision machining is crucial and how services are necessary to ensure each […]

Build a Culture of Safety in Our Organization

A strong safety culture is the backbone of any successful health and safety environment program. It exceeds compliance with regulations, it’s about developing a culture where employees value safety in all their work. In 2025, with changing workplace hazards and emerging technologies, establishing a safety-oriented culture is more important than ever. The following explains why […]

How CMM Inspection and Reverse Engineering Drive Manufacturing Excellence

Reliability and accuracy in each component are necessary in the contemporary manufacturing era. Two technologies, reverse engineering and CMM inspection, are forces that transform these into reality. Precision and accuracy are the utmost priorities at Accurate Edge. This blog explains why these technologies are necessary and how they enhance manufacturing processes. What is CMM Inspection? […]

Delivering Depth and Precision—Your Partner in Deep Hole Drilling Excellence

Certain complex specific industries require precision, resulting in higher demands for internally feature-specifically produced parts. Deep-hole drilling is an important process that allows the accurate production of parts. With the latest technology and advanced deep-hole drilling techniques at Accurate Edge, parts can be manufactured to meet exact specifications. This ensures world-class quality, precision and reliability […]

How CNC Machining Services Enhance Machining Productivity

How CNC Machining Services Improves Productivity? CNC machining services are changing the manufacturing process. With a growing need for precision engineering, the CNC machining market worldwide is expected to develop at a rate of 6.6% CAGR until 2030. CNC machining services can optimise efficiency by reducing processes, using total resources, and incorporating technology. Organizations leverage […]

Enhanced Strength Through Long Jobs Machining and Honing

Enhanced Strength Through Long Jobs Machining and Honing Enhanced Strength Through Long Jobs Machining and Honing Why Strength is Important in Heavy Engineering Heavy engineering parts need to absorb impact, fatigue, and high stress. Their strength to do so depends on tensile strength, yield strength, impact resistance, and fatigue life—all critical in preserving operating integrity […]

How Advanced Precision Machining Supports Lean Manufacturing Practices?

What are Lean Manufacturing Processes? Lean manufacturing processes seek to minimize waste and maximize efficiency in production. They follow key principles such as continuous improvement (Kaizen), just-in-time (JIT) production, and defect prevention to ensure optimal utilization of resources. Lean production enhances cost reduction, productivity, and product quality by eliminating unnecessary steps, reducing material waste, and […]